Automation and Robotic Preventative Maintenance

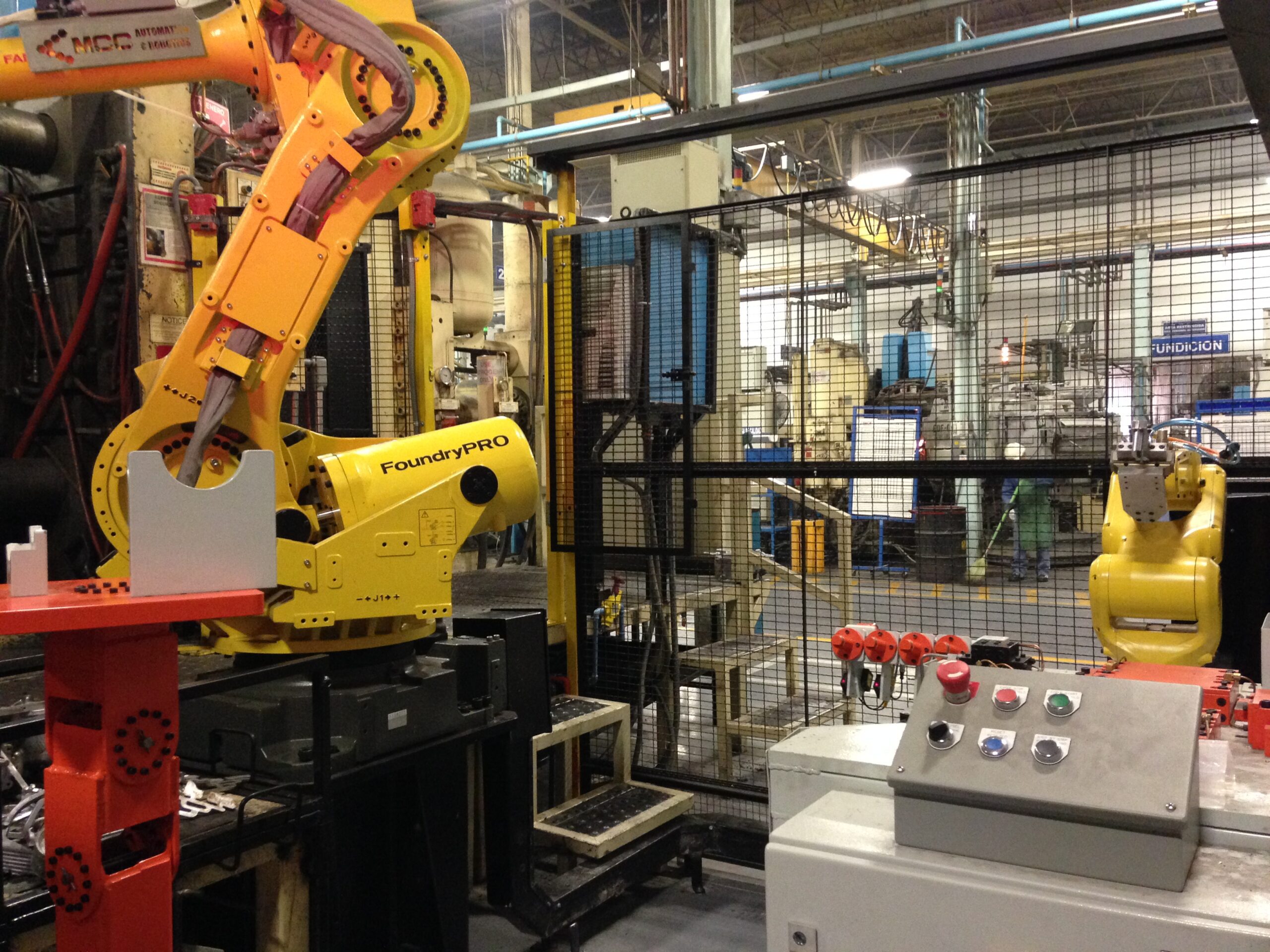

Preventative maintenance is no longer optional - it's essential for maximizing robot performance and avoiding costly downtime. Multi-Craft Contractors, a leader in Automation and Robotics Preventative Maintenance in Northwest Arkansas, Springdale, AR, Fort Smith, AR, Springfield, MO, and across the USA. We deliver a proactive approach, ensuring peak robot health and outpacing reactive repairs.

Robotics in Modern Work Environments

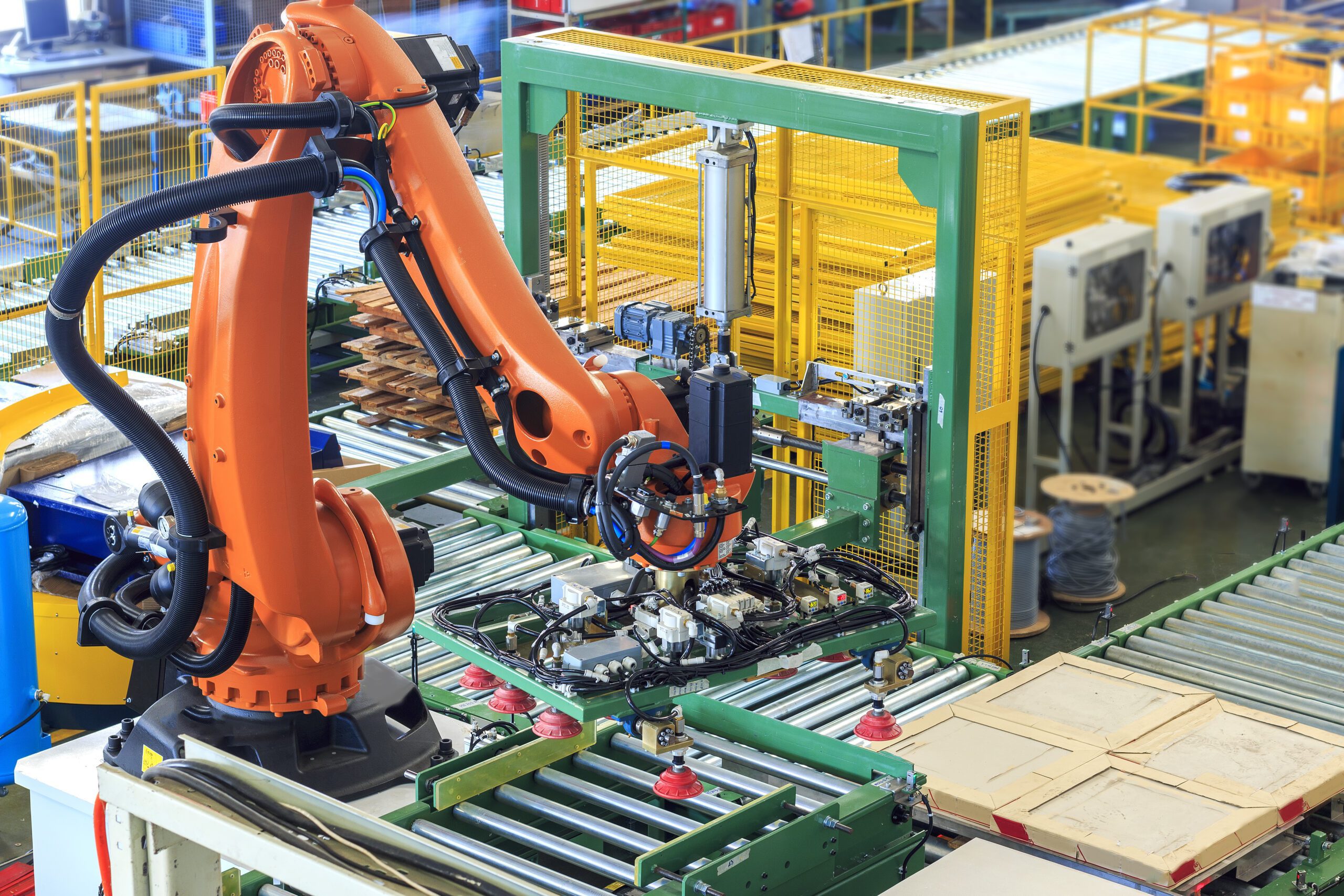

Modern factories are transforming into intelligent ecosystems, where robots communicate and manage their own maintenance. This presents exciting opportunities for efficiency and productivity, but also demands skilled workers, robust cybersecurity, and strategic planning.

MCC Automation empowers you to navigate the complexities of intelligent manufacturing facilities. We offer a comprehensive suite of solutions, including:

- Remote Monitoring and Diagnostics: 24/7 access to our experts, ensuring proactive maintenance and optimal robot performance.

- Cybersecurity Solutions: Safeguard your systems from unauthorized access and ensure reliable robot operation.

- Workforce Development: Upskill your technicians for the demands of intelligent equipment and remote maintenance.

- Strategic Planning and Scheduling: Optimize the lifespan and performance of your entire equipment portfolio.

Maintenance Tasks for Your Robot's Lifespan

- Backing up the controller memory

- Check connections and other equipment for functionality

- Clean vents and filters with compressed air

- Durability and repeatability testing

- Grease joints according to specs

- Inspecting robot harness and cables

- Inspection and cleaning

- Inspection of brake operation

- Load testing to ensure OEM specifications for performance are met

- Repair/replacement of components as per contract agreement

- Test and replace RAM and APC batteries, if required

- Visual inspection of controller cables.

Consequences of Neglecting Preventative Maintenance

By not being proactive with regular preventive maintenance for your robotic equipment the following issues may arise:

- Cable Damage

- Loss of Programs

- Position Deviation

- Repeatability Issues

Automation and Robotics Expert for Superior Strategies

Maximize your robot's efficiency with Multi-Craft Contractors. Our experts leverage in-depth knowledge across industries to develop clear strategies for managing robotic operations. We combine new technologies with proven manufacturing practices to optimize your workflow. Avoid costly downtime and ensure peak performance. Contact Multi-Craft Contractors today!