The face of manufacturing is changing dramatically. Advanced automation technologies are combining with the skills of the workforce, bringing a new aspect to this industry.

As automation becomes more complex, there is a growing need for skilled workers who can effectively integrate and maximize the use of these technologies.

Advanced Manufacturing Skills

While the above skills are relevant, a few of the advanced manufacturing skills now in demand include:

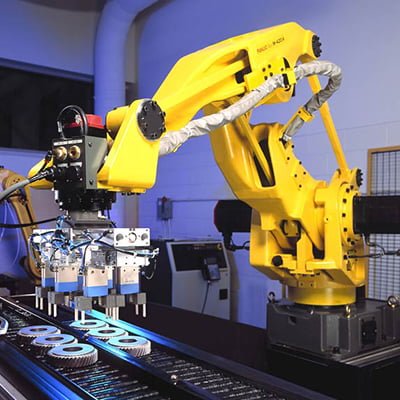

- Robotics and Programming: Knowing how to program and control robots is very important for making automated systems work well. This includes everything from basic knowledge to advanced skills in programming languages, how robots move, safety rules, and more.

- Data Analytics: Gathering, analyzing, and understanding data helps make smart decisions and improve the manufacturing process. Skills in data analytics allow manufacturers to spot patterns, boost efficiency, and keep making better products.

- Internet of Things (IoT): IoT will revolutionize manufacturing because all machines, equipment, and systems will be connected to analyze real-time data. Workers who understand IoT can use this to streamline production, reduce downtime, and increase overall productivity.

- Cybersecurity: As manufacturing operations become more connected, protecting them from cyber threats is now a top concern. Employees with cybersecurity skills can safeguard important data and prevent cyber-attacks that could harm manufacturing systems.

- Additive Manufacturing: Additive manufacturing, also known as 3D printing, is a growing technology that lets you make complex parts and products directly from digital designs. Having more experts in this area will help workers use this technology to save time, reduce waste, and create products tailored to specific customer needs.

The Future of Work in Manufacturing

The future of work in manufacturing will likely involve a close partnership between human workers and advanced automated technologies. As automation improves, the emphasis will move to tasks that need human judgment, creativity, and problem-solving abilities.

Key Trends in Manufacturing

- Reshoring and Regionalization: With supply chain problems happening more often, there's a rising move to bring manufacturing back to where companies are based, so they don't depend as much on foreign suppliers. This change is likely to bring new jobs and help the economy grow in areas where manufacturing is important.

- Sustainable Manufacturing: As people want more eco-friendly products and methods, companies are starting to use greener ways to make things. This means cutting down on trash, saving energy, and using materials that are good for the environment.

- Industry 4.0: Industry 4.0 involves adding digital technology to manufacturing, making everything connected and automated. This change is expected to lead to new ideas, better performance, and stronger competition.

- Predictive Maintenance: Downtime on production machinery costs additional labor and valuable production revenue. Predictive maintenance looks to use data and analytics to estimate machine life and schedule maintenance on normally scheduled downtime. This helps to limit production downtime by managing repairs effectively.

- Workforce Shortages: With the growth projected to continue in the manufacturing sector projected and the rate of retirement for skilled workers, companies must look to automation to fill gaps in the workforce.

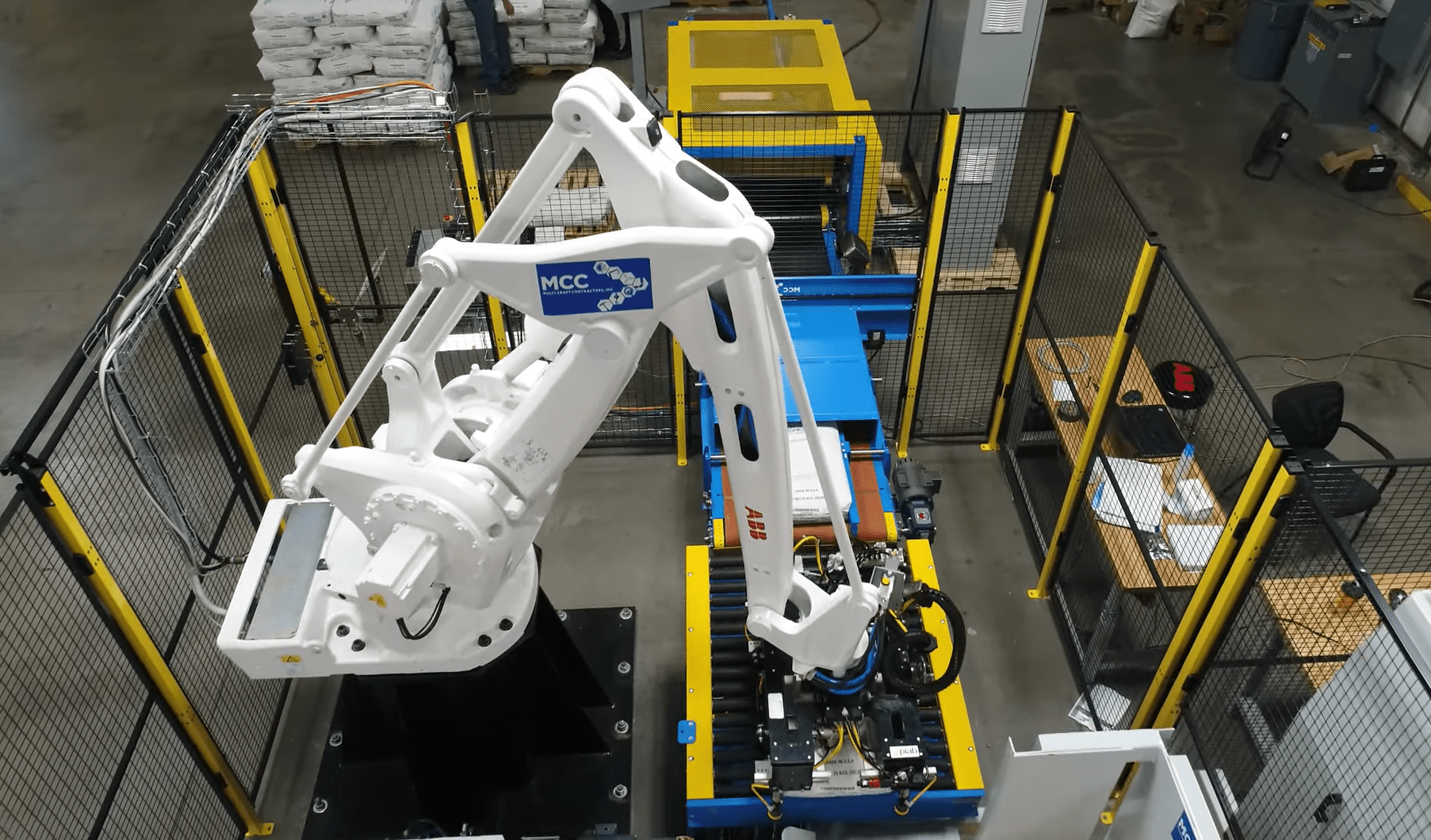

The Role of MCC Automation in Shaping the Future

MCC Automation can assist you in improving efficiency, boosting quality, and increasing your business's competitive edge by integrating the most advanced automation technologies. We provide a full range of automation solutions and services tailored to help our clients reach their objectives and stay ahead in the market.

How MCC Automation Can Support Your Business:

- Automation assessment: Identifying your specific automation needs and goals.

- Solution design: Developing customized automation solutions tailored to your unique requirements.

- Implementation and integration: Seamlessly integrating automation technology into your existing operations.

- Training and support: Providing comprehensive training to your staff and ongoing support to ensure optimal performance.

By teaming up with MCC Automation, you can use the most advanced automation tools to boost efficiency, enhance quality, and strengthen your business's competitive edge. Click here to find out more and get in touch with us.